Expert Reserch & Development Teams

KDW has our own R&D team, which focuses on researching and developing flexible packaging and materials, Product Specifications Management, and Regulatory Compliance Management…

With extensive experience in flexible packaging, Kinderway can continue pushing the envelope with new structures, new materials, recyclable packaging, improved sustainability, and more.

Our Advanced Equirement

While possessing a team of proficient R&D experts, the indispensability of state-of-the-art R&D testing equipment cannot be overstated.

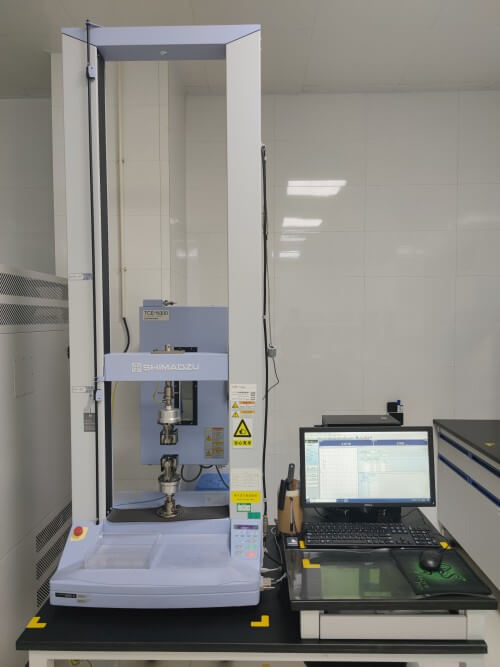

Electric Universal Tester

The electric universal tester is to assess and measure various mechanical properties of the pouch material. This testing equipment applies controlled forces and measures the corresponding responses to evaluate the strength, flexibility, and overall performance characteristics of the plastic pouch.

Xenon Lamp Weather Resistance Tester

The xenon lamp weather resistance tester is to simulate and assess the effects of outdoor weather conditions, particularly sunlight exposure, on the durability and performance of the pouch material. By subjecting plastic pouch samples to controlled exposure to this simulated sunlight, the tester can evaluate the pouch’s resistance to UV degradation, color fading, material aging, and other weather-related factors.

Molud Incubator

The mould incubator is to study the susceptibility of plastic pouch materials to mold growth, assess the effectiveness of anti-microbial treatments or packaging solutions, and evaluate the overall mold resistance of plastic pouches. By simulating real-world conditions, mold incubators help in identifying potential mold-related issues, ensuring the quality and safety of plastic pouches, and developing strategies to prevent mold contamination during storage or transportation.

Electro- thermal Incubator

The electro-thermal incubator is commonly used for tasks such as heat sealing, drying, curing, or testing the heat resistance of plastic pouches. It ensures consistent and uniform heating throughout the incubation chamber, allowing for reliable and efficient processing of the pouches.

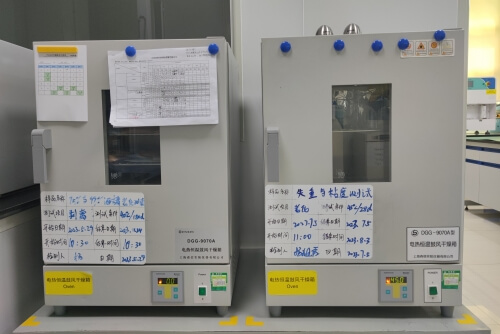

Electric thermostatic air drying oven

The mould incubator is to study the susceptibility of plastic pouch materials to mold growth, assess the effectiveness of anti-microbial treatments or packaging solutions, and evaluate the overall mold resistance of plastic pouches. By simulating real-world conditions, mold incubators help in identifying potential mold-related issues, ensuring the quality and safety of plastic pouches, and developing strategies to prevent mold contamination during storage or transportation.

Gelbo Flex Tester

The Gelbo Flex Tester is a specialized testing equipment used to assess the flexural resistance and flexibility of plastic pouches. It is designed to simulate repetitive flexing or bending movements that the pouch may experience during handling, transportation, or use.

Hot Tack Tester

The hot tack tester is to simulate the sealing process of plastic pouches by applying heat and pressure to create a seal between two layers of the pouch material.

Coefficient of Friction Tester

The Coefficient of Friction (COF) Tester is a specialized testing equipment used to measure the frictional properties of the pouch material. It assesses the interaction between two surfaces of the pouch, typically the inner layers or the pouch material and a specified testing surface.

UV/Vis Spectrophotometer

The UV/Vis (Ultraviolet/Visible) spectrophotometer is to measure the absorbance or transmittance of light by the pouch material at specific wavelengths within the UV and visible spectrum. This analysis provides valuable information about the material’s optical properties, such as transparency, opacity, and color.

Fourier Infrared Spectrometer

The Fourier Infrared Spectrometer (FTIR) is a powerful analytical instrument used to analyze the chemical composition and molecular structure of materials, including plastic pouches, to identify and characterize the types of chemical bonds present in the pouch material.

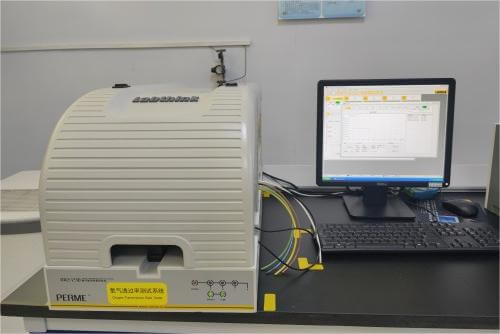

Oxygen Transmission Rate Tester

The Oxygen Transmission Rate (OTR) Tester is used to measure the rate at which oxygen permeates through the pouch material. It provides valuable information about the pouch’s barrier properties against oxygen, which is crucial for products that require protection from oxygen exposure.

Water Vapor Transmission Rate Tester

The Water Vapor Transmission Rate (WVTR) Tester is used to measure the permeability of the pouch material to water vapor. It assesses the rate at which water vapor can pass through the plastic pouch, indicating its barrier properties against moisture.

Microscope

The microscope is used for magnifying and examining the surface and internal features of the pouch material at a microscopic level. It allows for detailed inspection and analysis of the pouch structure, morphology, and any potential defects or imperfections.

Oxygen Permeation Analyzer

The Oxygen Permeation Analyzer is used to measure the oxygen permeability or transmission rate of the pouch material. It assesses how effectively the pouch can prevent the ingress or egress of oxygen, which is important for products that are sensitive to oxygen exposure.

Water Vapor Permeability Tester

The Water Vapor Permeability (WVP) Tester for plastic pouches is used to measure the water vapor permeability of the pouch material. It assesses the ability of the pouch to allow water vapor to pass through it, indicating its barrier properties against moisture.

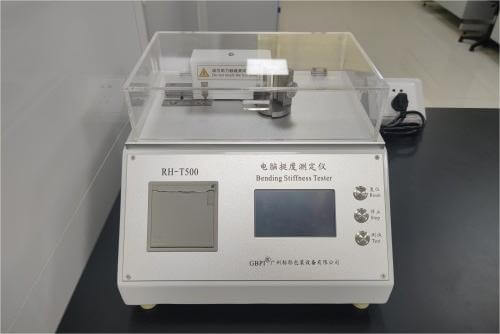

Bending Stiffness Tester

The Bending Stiffness Tester is to quantify the resistance of the plastic pouch material to bending or flexural deformation. This test helps evaluate the stiffness, flexibility, and overall mechanical properties of the pouch.

Variable-speeed Multipurpose Oscillator

The variable-speed multipurpose oscillator is used in various pouch processing and manufacturing applications. It provides adjustable oscillation or vibration at different speeds, offering flexibility and versatility in handling different types of plastic pouches and processes.

50+ Patens

In the realm of flexible packaging, KDW has pioneered numerous patented packaging pouch designs and structural innovations. These proprietary inventions demonstrate our ingenuity and expertise in developing cutting-edge solutions that push the boundaries of packaging technology. Our portfolio of pouch type patents and structural patents exemplifies our commitment to innovation and distinguishes us as industry leaders in the field of flexible packaging.

Please see some of our patents. Contact us if you need more patents.

Pouch Structure Patent

Food Pouch Patent

Spout Pouch Patent

Stand Up Pouch Patent

Pouch Structure Patent

Pouch Patent

Start With KDW

+86 13559233681(Wechat, Whatsapp)

No1, Anbian Rd, Torch High-Tech Zone (XiangAn), Xiamen, Fujian, China